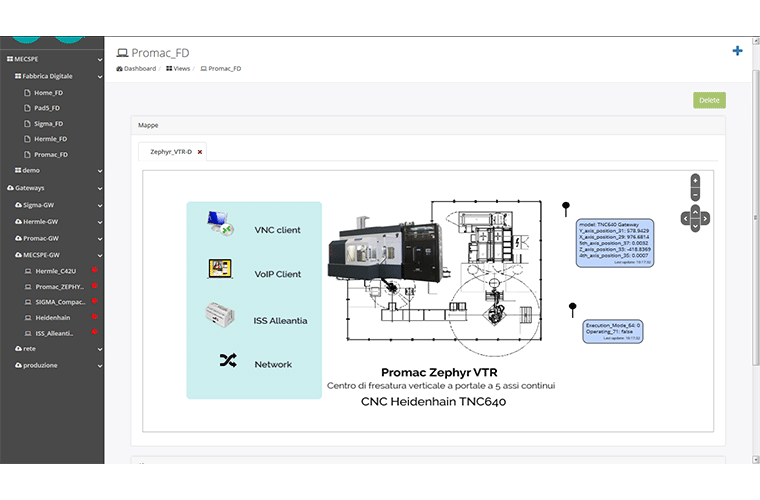

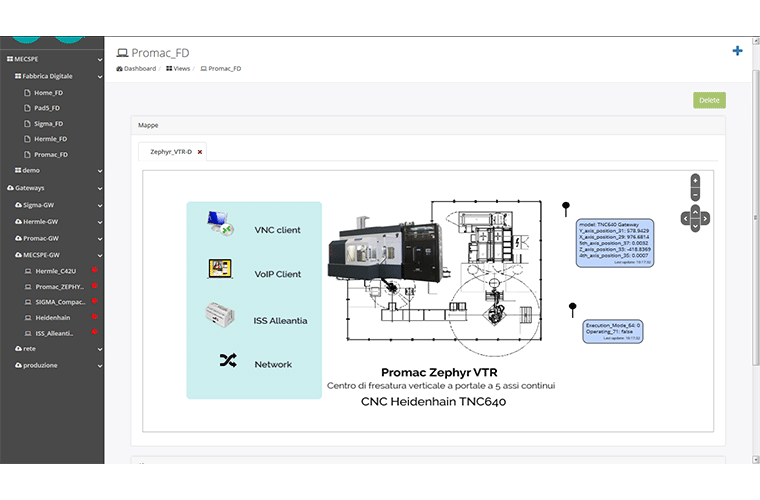

The project aims at designing, implementing and verifying in real-world factory scenarios the Plug&Play Smart Factory (PPSF) solution. PPSF enables the creation of Industry 4.0 services on top of a versatile Industrial IoT structure composed of CPS (Cyber Physical System) Gateways gathering data from and communicating with production lines systems and an Industrial IoT service platform able to create and manage industrial services effortless.

The goal is to allow Plug&Play gathering and management of factory data without the burden of developing custom hardware or software, leveraging a ‘smart middleware’ concept. We will use the STM32 Microcontroller Platform specifically for the I/O shield of the CPS Gateway, to build up a versatile off-the-shelf, plug size, CPS Gateway capable to connect to a large variety of industrial devices, programmable logic controllers, sensors, and actuators, through the Alleantia Middleware. Once plugged, the CPS Gateway will exploit the Alleantia device modelling tool and Library of Things (supporting more than 4000 devices) to dynamically discover available devices and link them to the Stoorm5 IoT Application Platform, enabling remote control and management without any customization activity.

The sought-for result is an affordable production control centre seamlessly populated with heterogeneous virtual devices that can be further orchestrated and adapted to provide tailored industrial services. The project value chain starts from the use of a low cost CPS Gateways that can be massively produced and deployed, going through a real plug&play process to effortlessly connect industrial equipment to the cloud, and ends by having a ready-to-use collection of heterogeneous industrial devices managed through the Stoorm5 IoT platform. PPSF can have a real impact on industrial processes, by allowing the extensive use of IoT technologies in production lines in a cost-effective manner, suitable to any kind of enterprise, especially SMEs. We plan to extensively test and verify PPSF in a set of selected production lines in the Whirlpool Europe plant located in Biandronno (VA, Italy), committed to support this project. The trials will prove the effectiveness of PPSF in terms of faster deployment, easier management, and cost reduction.

|

|